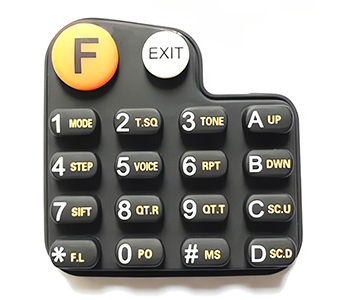

How to make the Silicone Control Panel/Keypad?

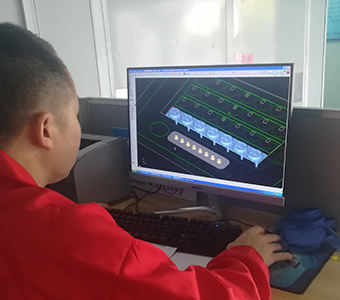

1. Drawing design, provide a 3D drawing and description file

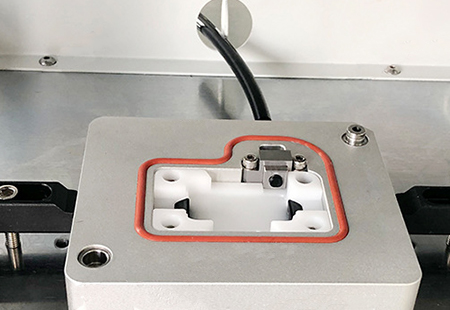

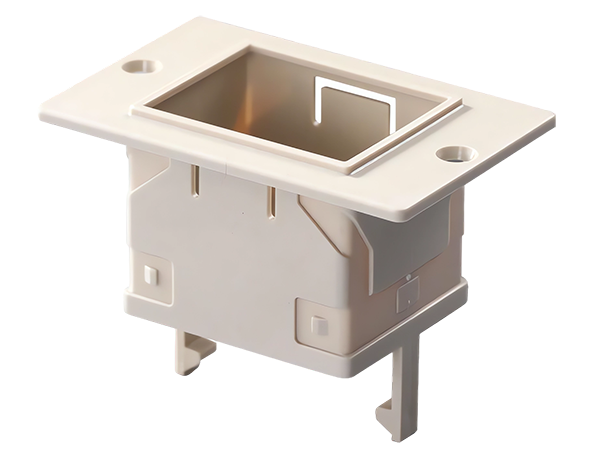

2. Make a tooling according to your 3D drawing

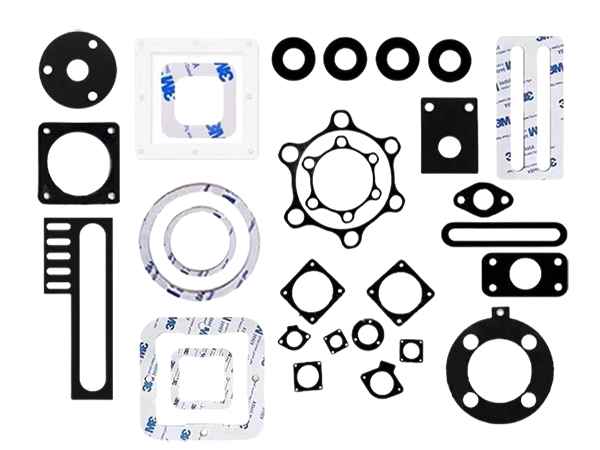

3. The following processes are used to complete sample making or production:

- Compression Molding

- Spraying Black & white Oil

- Laser etching

- Silk printing

- PU/Matte oil Coating

- Finishing

- Quality checking