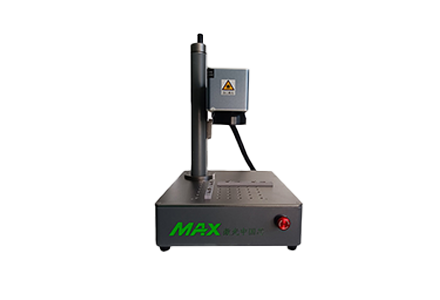

Laser Machine For Production

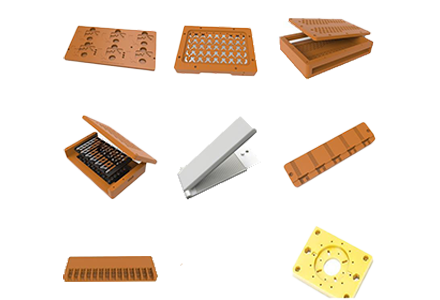

10 units

10 units

4 units

150 units

Single Laser Etching Button

Square Laser Etching Keypads

Customized Laser Engraved Keypads

Receive detailed Design for Manufacturability reports within 24 hours—your blueprint to seamless production.

Experience rapid prototyping with sample molds crafted within 3-5 days—accelerating your product development journey.

From concept to reality: Our streamlined process delivers production molds in 7-25 days, ensuring efficiency without compromise.