- Client: Flyaudio

- Automobile industry

From delivery speed to product performance, this manufacturer has always exceeded our expectations. We’re eager to continue working with them!

Fireproof rubber

Conductive rubber

Medical rubber.....

Flame retardant, mildew proof, anti-aging

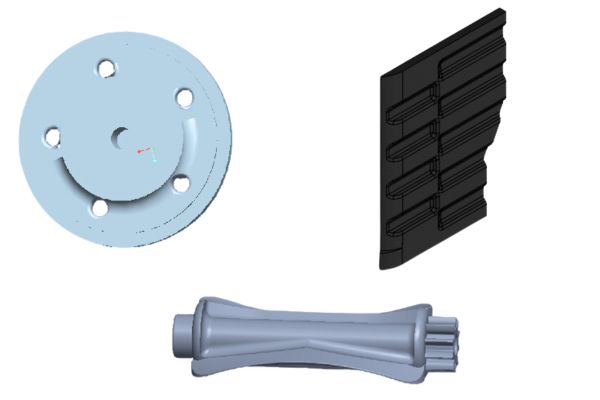

Support any shape customization

diameter or width

all colors

any needs please let me know

oem/odm Manufacturer

specialist reply

7*24H respond

Covering all processes

refund prototypo mold cost

1.Product structure inspection

2.Product performance analysis(Acid-base resistance/high elasticity)

3.Product delivery date

4.Product cost analysis Custom Solutions

5.Provide suitable customized solutions, including structural adjustment/delivery time/project cost, etc

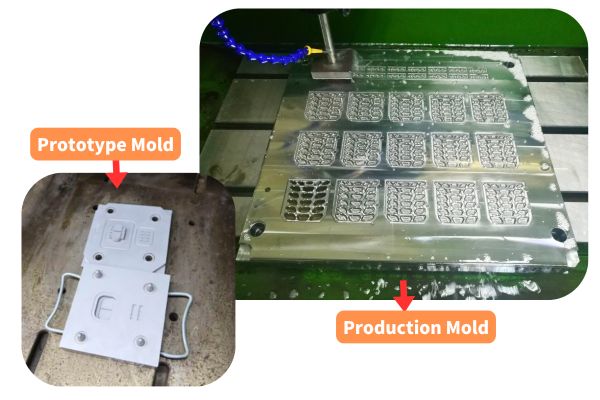

1.Check product design feasibility

2.Confirm the final design with the client

3.Choose the right steel for the mold (50# steel is common)

4.Making prototype molds5.Making Production molds

According to different usage requirements

1.Common Silicone

2.High temperature resistant silicone

3.Conductive Silicone

4.Flame retardant silicone

5.Medical Silicone

6.....

1.Compress Process

2.Printing Process

3.Spraying Process

4.Laser Etching Process

5.Backing Adhesive process

6.Over-Molding Process

1.Free prototype mold adjustments

2.Provide the number of samples requested by the customer

3.Rapid Proofing Service

4.The sample is not qualified, can be re-sampled and adjusted until qualified.

1.Check the product data card before making the goods

2.Check product tolerances

3.Check product appearance

4.Checking product performance

1.Support customized packaging, opp bags/cartons and other customized requirements

2.Global logistics services via DHL/FedEX/UPS/TNT, etc.

3.Support for Amazon shipping

4.Support shipping to your agents

5.Support your agent in checking the goods before shipment.

From delivery speed to product performance, this manufacturer has always exceeded our expectations. We’re eager to continue working with them!

Their customer service team is very professional, promptly answering all our questions about the product. The service is excellent.

Their production capacity is impressive, with fast delivery times. Every large order is completed within the expected timeframe.

Fromrubber has over 8,000 custom project experiences to enhance your customization and reduce risks. Start your first project now!. We are always here to solve your problems.