How are custom silicone keys made?

Usually before Customing silicone keys, you need to confirm the product's hardness, color, process and other information. (For more information, please see my previous FAQ-What information is required to customize silicone products?)

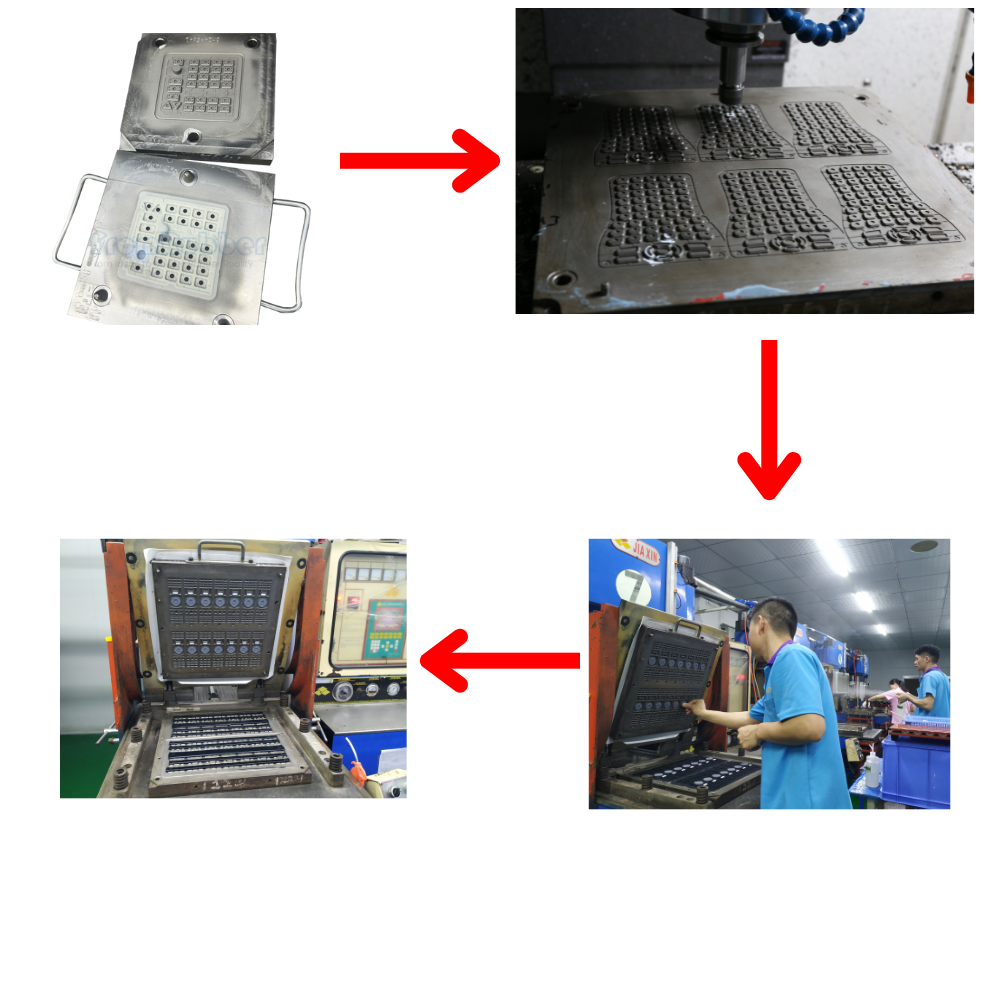

1.Through STP Design, engineers design CNC programs to carve the required shapes on the steel.

2.After the prototype mold is made, the raw materials are refined. The required colors and special properties are added in this step.

3.Cut the raw materials into corresponding small pieces, put them into the mold and press them into the corresponding shape. This step is to transform the customer's design into an actual sample. The actual installation will show the test effect.

The above is a sample production process. The following document is a detailed silicone rubber product customization process. If you happen to be customizing silicone rubber products, you can refer to the process.

If you have any questions, you can also contact my email (Karl@fromrubber.com), so that I can help you faster